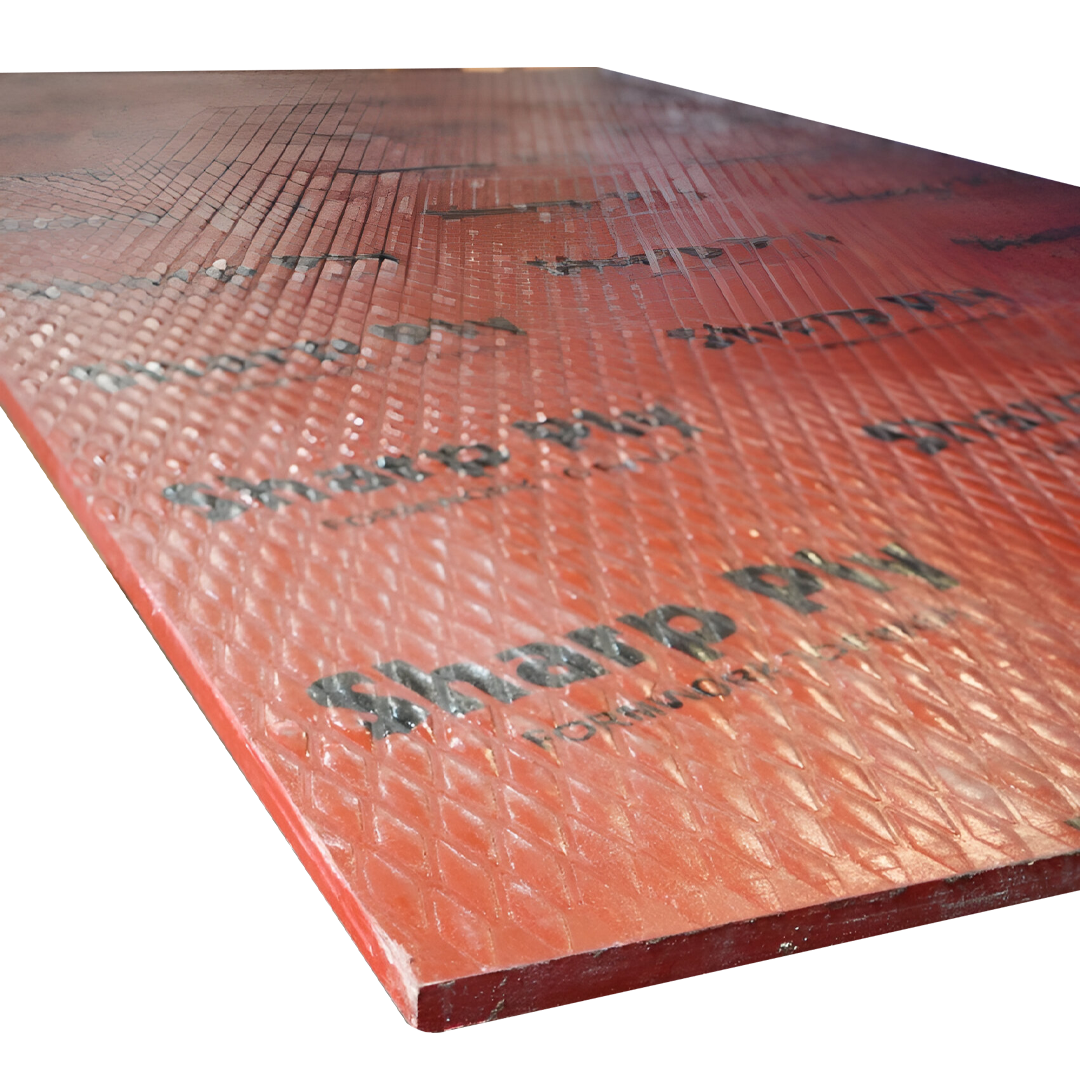

Compressed Truck Flooring

Sharp Ply has an extraordinary long life densified flooring to offer for Container Flooring. Manufactured with state-of-the-art processes, this product provides a friction-resistant anti-skid surface, bonded with superior grade adhesives making it a high density plywood endowed with excellent strength, durability and all weather resistance

Aditya Densified Container Flooring is manufactured from veneers peeled from eco-friendly plantation timber and carefully seasoned to the required 6% moisture content. These Veneers are rotary cut, smooth and free from knots and splinters. Two layers of metal wire-mesh reinforcements are added into the veneers and then impregnated with thermosetting adhesives conforming to IS: 848: 1974. Final densifications of the veneers is done under controlled condtions of high temperature and pressure.

Advantages

Aditya Densified Chequered floor boards for Truck, Bus, Rail Coach, Boat, Ship Flooring, Industrial and Cold storage Flooring

Applications of Densified Plywood

Product Specifications

| Properties | SAL | Floor Board |

|---|---|---|

| Density | 0.9 gm/cc | 1.00gm/cc |

| Compressive strength | IS: 1708 (Part-II) - 1986 | 9% |

| Parallel to laminate | 1041 kg/cm2 | 1811.37 kg/cm2 |

| Perpendicular to laminate | 627.67 kg/cm2 | 700 kg/cm2 |

| Static bending strength Along the grainAcross the gain | 1750 kg/cm2 300 kg/cm2 |

1800 kg/cm2 900 kg/cm22 |

| Impact Strength Edge wise Hardness Hardness | 30.10 kg/cm2 | 35.16 kg/cm2 750kg/cm2 |

| Perpendicular to laminate | 124kg/cm2 | |

| Hardness (Rockwell 'H'Scale)Water absorption in 24 hrsSwelling in boiling water in 8 hrs. | 45% 15% 19% |

55% 6% 10% |

| Sizes | Value |

|---|---|

| 18mm for light vehicles, 25mm for medium vehicles, 35mm for heavy vehicles | 35 mm, 60 mm |