Compressed Chequered Flooring

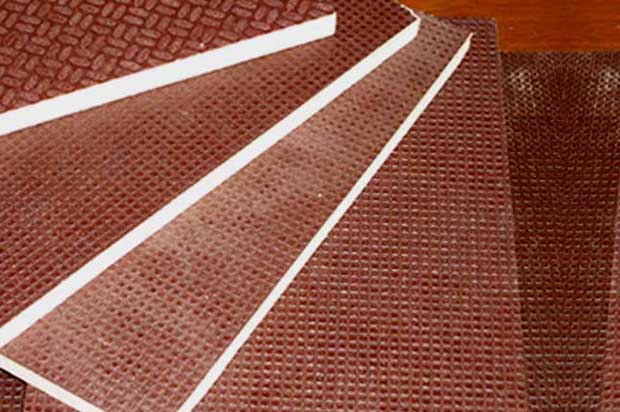

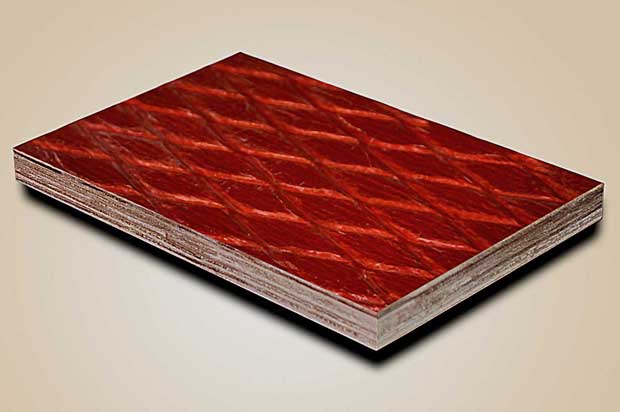

These densified wooden chequered floor boards are manufactured from local plantation timbers, under strict quality control with german collaboration. The unique friction-resistant, anti-skid chequered surface is bonded with superior grade phenolic resin. This medium-density compreg plywood possesses excellent strength, durability and all weather resistance.

Aditya Densified Chequered floor boards are available in resin-impregnated, film face and metal-clad variants. A sound-absorbing floor board, which reduces noise level by 21 db, can also be provided. Each type of floor board can be supplied up to a size of 3.2 meters X 1.75 meters per sheet. The ply conforms of IS: 3513 Part-2 (Medium Density) and is used by a majority of state transport corporations in india.

Advantages

Aditya Densified Chequered floor boards for Truck, Bus, Rail Coach, Boat, Ship Flooring, Industrial and Cold storage Flooring

Applications of Chequered Floor Boards

Product Specifications

| Properties | Results | Value |

|---|---|---|

| Density | IS: 4990 : 1993 | 0.96 gm/cc |

| Moisture content and volatile content | 85 N/mm 49 N/mm |

|

| Water absorption in 24 hrs. | IS: 4990 : 1993 | 102 N/mm2 67 N/mm21 |

| Cross breaking strength Along the grainAcross the grain | IS: 1998 ( ) : 1962 | 1300 kg/cm2 650 kg/cm2 |

| Tensile strength Along the grainAcross the grain | IS: 1734 (Part-9) - 1983 | 900 kg/cm2 |

| Compressive strength | AS: 109:63 Feb:2002 | 900 kg/cm2 |

| Izode impact test | IS: 1708 (Part-I) - 1986 | Pass the test |

| Parallel to laminate | 65 kg/cm2 | |

| Perpendicular to laminate | 40 kg/cm2 | |

| Swelling in boiling water after 8 hrs. | AS: 109: 63 Feb. 2002 | 10% |

Technical Properties of Aluminium Chequered

| Density | Results | Value |

|---|---|---|

| Density | IS: 1708 (Part-2) -1986 | |

| Moisture content and volatile content | IS: 1708 (Part-1) -1986 | |

| Water absorption in 24 hrs. | AS: 109.63 : Feb. 2003 | 2.5% |

| Cross breaking strength Along the grainAcross the grain | IS: 1998 : 1962 | 1500 kg/cm2 1400 kg/cm2 |

| Tensile strength Along the grain Across the grain | IS: 1734 (Part-9) -1983 | 900 kg/cm2 935 kg/cm2 |

| Izode impact test | IS: 1708 (Part-I) - 1986 | Pass the test |

| Parallel to laminate | 65 kg/cm2 | |

| Perpendicular to laminate | 40 kg/cm2 |